REVOLUTIONARY DEVELOPMENTS

Groundbreaking innovations for forklifts

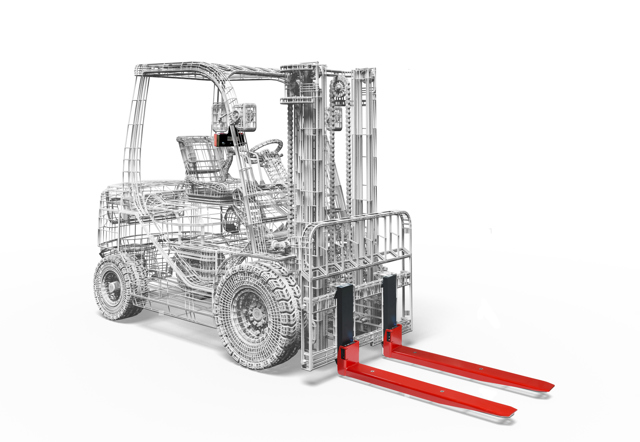

In the hectic and busy logistics world, efficiency in warehouse management and supply chain is crucial. Forklifts, an indispensable part of warehouse operations, are at the center of this evolution through the integration of advanced technologies. These technological breakthroughs are not only a step forward in increasing operational efficiency, but also contribute to areas such as safety and sustainability. This blog explores five innovative technologies that are transforming forklift functionality. These innovations offer significant benefits to logistics companies and set the tone for the future direction of the industry. From advanced weighing solutions to energy-saving technologies, let's explore how each innovation can improve the warehouse environment.

Innovation 1: Mobile weighing

The most important development for forklifts if you ask us is, of course, the ability to do mobile weighing. While industrial floor scales were part of the standard equipment in the manufacturing and distribution industry for many years, they also proved to be a slowing factor in logistics processes. By integrating weighing technology into equipment, such as hand pallet trucks, electric warehouse trucks, stackers and forklifts, real-time data on material flows can be generated. This not only improves efficiency, saving you valuable time, but also helps reduce costs. With mobile weighing, you will notice an increase in efficiency in your warehouse operations from day one.

In addition, the IFOY Award nominated Weigh in Motion technology on a RAVAS iCP offers the ability to weigh loads while a forklift is still in motion. "Weigh in Motion provides accurate and reliable weight determination while a forklift is in motion. This results in time savings and cost reductions, as the operator can weigh without stopping," said Michael van Dijk, International Key Account Manager at RAVAS. This makes this award-winning technology ideally suited for moving large quantities of palletized goods within a short time frame, for example for logistics, warehousing, re-movement and LTL shipments.

Joanna Ślażyńska, Project Coordinator at DPD Poland

"The integration of this solution has created a nice synergy within our daily operations. The ability to take measurements without having to drive our vehicles to a static scale has made our cross-docking processes much more efficient."

Innovation 2: Energy-saving solutions

Sustainability is an increasingly important concern in the logistics industry. Modern forklifts embrace innovations that improve energy efficiency. The integration of electric drive technologies and the optimization of energy management systems play a crucial role in achieving higher sustainability.

An example of one such innovation is improved battery technology. Contemporary forklifts are increasingly equipped with lithium-ion batteries that offer higher energy density and allow for faster charging. These advances improve equipment autonomy and durability, resulting in exceptional performance and minimal downtime. These technological improvements help reduce operational costs while reducing the carbon footprint of warehouse operations. Through more efficient energy use and the reduction of harmful emissions, these systems support a greener and more sustainable future for the logistics industry.

Innovation 3: Cloud-based fleet management

The next innovation is cloud-based fleet management through GemOne, a system offered by one of our partners. This technology enables companies to efficiently manage their forklift fleets through real-time access to data on each forklift's performance, maintenance needs and usage patterns. This helps optimize resource utilization, schedule preventive maintenance and increase overall productivity. With cloud-based technology, managers can make decisions from any location based on the most up-to-date information, resulting in a more connected and responsive operational structure.

Innovation 4: Increased security

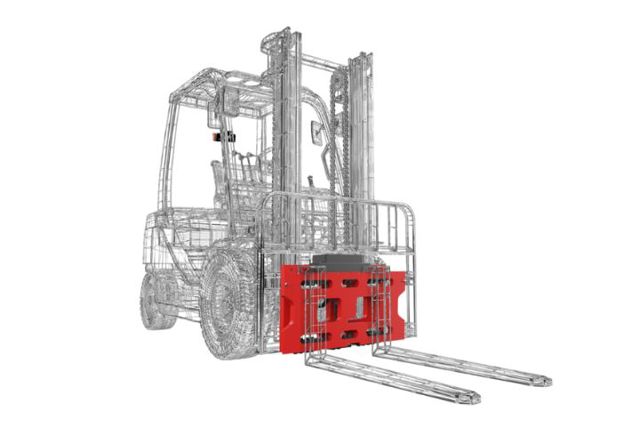

The next innovation on our list is the RAVAS SafeCheck, an advanced safety technology designed to improve the safety of forklift operations. Because, of course, safety always comes first.

This technology integrates sensors and systems that continuously monitor the condition of the forklift and its surroundings. By providing warnings of potential risks, such as overloading, RAVAS SafeCheck helps prevent accidents and ensure the safety of both the operator and the environment. This system is essential for companies striving to create a safer workplace and minimize industrial accidents.

Innovation 5: Linking with TMS, WMS or ERP systems

By integrating real-time weighing data into existing ERP, WMS or TMS systems, forklifts are transforming from traditional equipment to advanced information collection platforms that play a strategic role in logistics workflows. Accordingly, this fifth innovation in forklifts concerns the ability to seamlessly integrate real-time weighing data with Transportation Management Systems (TMS), Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems. These technological advances make it possible to significantly optimize operational processes.

Linking mobile weighing systems with management software not only contributes to more accurate inventory control and process optimization, but also helps make faster and more informed decisions. Moreover, this integration allows companies to improve margins by working more efficiently and reducing errors such as incorrect loading or inaccurate inventory levels.

Conclusion

Forklifts are being transformed by innovations that make them safer, more efficient and more sustainable. By integrating advanced technologies and systems, these indispensable tools in logistics environments are evolving into intelligent devices that contribute not only to operational improvements but also to strategic business goals. These technological advances offer new opportunities for optimizing workflows and increasing productivity, while simultaneously reducing the environmental footprint.

LEARN MORE

Frequently Asked Questions (FAQ)

What advantages do these innovations in forklifts offer?

Recent innovations in forklifts offer significant benefits such as increased efficiency, improved safety and reduced environmental impact. These technologies make logistics processes smoother and more sustainable, while also reducing operating costs.

How do these technologies affect forklift operators?

New technologies not only improve safety and comfort for drivers, but also increase their productivity and capabilities. Advanced systems such as mobile weighing and automated management allow drivers to work more accurately and efficiently. This not only facilitates the work itself but will also contribute to higher employee satisfaction.

How do safety innovations contribute to a safer work environment?

Safety innovations that provide notifications of potentially dangerous situations, such as overloading, significantly reduce the risk of accidents and injuries. They alert the driver to potential hazards, contributing to a safer work environment and a reduced risk of accidents.

What are the cost implications of implementing new forklift technologies?

Implementing advanced forklift technologies can initially seem like a significant investment, but these costs are often quickly recouped through the increased efficiency and cost savings these technologies provide. Systems such as cloud-based fleet management allow companies to monitor and optimize operations in real time, leading to significant savings in operational and maintenance costs. In addition, the increased efficiency allows work processes to run faster and with fewer errors, increasing overall productivity and shortening the payback period for investments.

Is additional training needed for employees to effectively use these new technologies, such as mobile weighing?

No, often additional employee training is minimal, or not needed at all, to effectively use RAVAS mobile weighing solutions. These technologies are designed to be intuitive, allowing users to quickly and easily begin using them without extensive prior training. This minimizes the transition for current personnel and facilitates the integration of advanced weighing systems into daily operations.