-

- Customer Stories

-

Optimize cross docking. A business case.

Optimize cross docking. A business case.

In this business case, one of RAVAS' logistic customers explored the possibilities to obtain the exact weight of each pallet in its cross docking operation, with the least possible impact on its loading and offloading procedures.

Obtain the exact weight of each pallet

In the cross docking operation

Business case cross docking

The weighing data in this business case should be integrated in the current software applications, with the least possible changes. The company selected RAVAS as a partner to equip both forklifts and electric warehouse trucks to realize these objectives. Significant benefits have been achieved through some investments in hardware and software and therefore the customer will continue to invest in RAVAS weighing systems for the next three years.

Intended results

The first intended result is to increase revenues by re-invoicing surplus pallet weight. Customers would declare a certain weight for their pallet loads, but upon arrival the real weight would be higher. Another intended result is to optimize load factors and prevent overloads. By knowing the exact weight of every pallet, truck loads can be planned exactly, optimizing load factors while avoiding overloads.

Investments in hardware and software

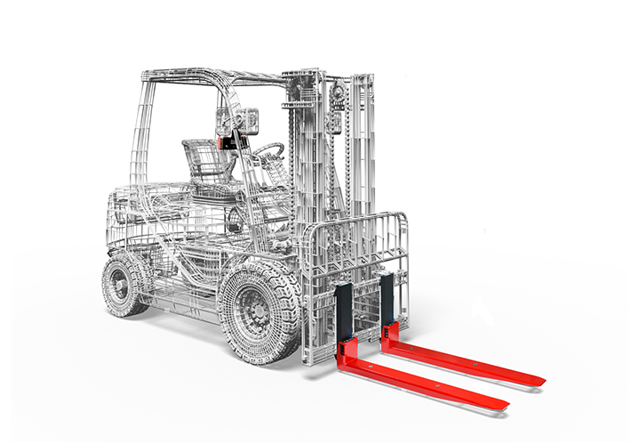

Forklift trucks and electric warehouse trucks were equipped with a RAVAS scale, integrated in the forks. The weight display on the truck is fitted with a WiFi module to communicate with the TMS (Transport Management System) over the wireless network. The weight scales are certified ‘legal for trade’, to allow invoicing of the weight measured. Handheld devices that emulate the TMS were already in use on the trucks. An app was built as communication interface between the TMS and the scale fleet.

The new work cycle

On every inbound pallet the label is scanned for ID. This triggers the TMS to interrogate the scale on the truck for the weight of the pallet. With the real pallet weight added, the data set is completed and can be used for invoicing and planning. In the new work cycle, pallet weights are obtained while lifting the pallet, without taking the goods out of the process. The truck operator only scans the label on the pallet for ID. The weight sampling is automated. The added weighing procedure has minimal impact on existing cross docking operations.

Two ROI studies

Two ROI studies were conducted by the RAVAS' customer. One was done before investing, as part of the business case.

Significant benefit

Another was done some time after installing the scales. Both studies proved a significant benefit from using RAVAS scales.

Continued to invest

The company has continued to invest in scales on their forklifts for three years now. A major efficiency boost.

Read more about cross docking?