Weighing while in motion

Weigh in Motion-technology

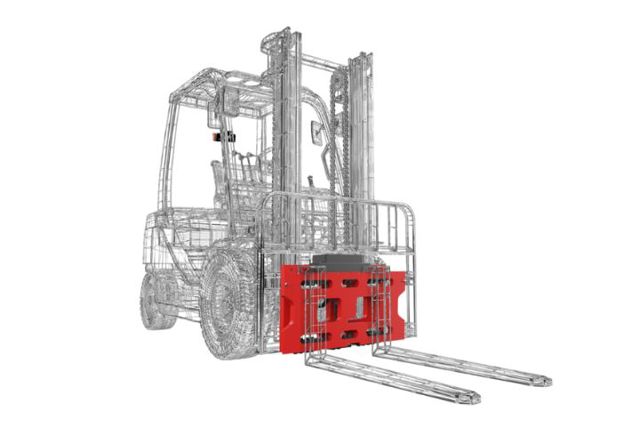

RAVAS, the market and innovation leader in mobile weighing systems for warehouse logistics and LTL shipping, is conducting successful pilots with the largest global logistics companies. The introduction of the RAVAS iCP with Weigh in Motion is scheduled for March 2024, at LogiMAT in Stuttgart.

Weigh in Motion offers efficiency and time savings as forklifts can weigh loads directly, eliminating the need for a separate scale. With this new technology, RAVAS ensures accurate and reliable weight, improving inventory management, logistics and quality control. Integration into forklifts reduces infrastructure costs and allows continuous monitoring during loading/unloading, optimizing loads and preventing overloading. Ideal for logistics, warehousing, reweighing and LTL shipping. RAVAS' Weigh in Motion technology, available from the second quarter of 2024 with iCP (Inteligent Carriage Plate) forklift scales, is designed for moving large volumes of goods quickly.

Thor van Rijk, R&D team leader at RAVAS

"Where drivers used to have to physically stop the forklift for several seconds to generate the weight, we have now developed automatic Weigh in Motion technology based on smart algorithms. Drivers can drive without having to think about generating the weight; the system controls the weighing automatically. This allows drivers to weigh on the go, without stops or interruptions. It doesn't even require the push of a button. RAVAS Weigh in Motion technology combines high-resolution and certified sensors with fast electronics and custom software that performs sensor fusion and smart algorithms. These algorithms automatically store the weight when the correct weight is calculated, enabling an optimal logistics process. OIML requires only that the system be zeroed out from time to time."

Introduction to the market

Bert de Greeff, Global Marketing Manager at RAVAS, said, "The RAVAS iCP with Weigh in Motion serves as a pre-building device for various makes and models of forklifts equipped with a FEM2 forkboard. It is capable of transmitting weight data wirelessly or via a wired connection. "We are excited about the upcoming launch of this innovative product at LogiMAT '24, where we will also unveil another groundbreaking product. Winning this award underlines our leading and innovative position in the logistics sector."

Michael van Dijk, International Key Account Manager at RAVAS: "During the pilots with some of the largest global logistics companies, data integration and automation were mentioned as additional benefits of the RAVAS iCP Weigh in Motion system. Wirelessly sharing data with warehouse management systems or other software applications enables automated data collection, storage and analysis. This integration streamlines the process of capturing weight information, improves inventory accuracy and facilitates data-driven decision making."