By choosing the most accurate technology and focusing on process optimization, you can save time and reduce errors, often of a human nature. Especially the food industry can benefit from mobile weighing technology.

Accuracy often translates into safety, quality and cost savings. This is especially true in the food industry, where weighing materials and ingredients is an important activity to ensure product consistency, safety standards, cost control and legal compliance. In this sector, employee experience counts, but the less we rely on manual operations, the fewer errors we encounter and the more accurate we can be. Errors affect timing, resulting in delays in the delivery of goods or, worse, the return of the product to the sender.

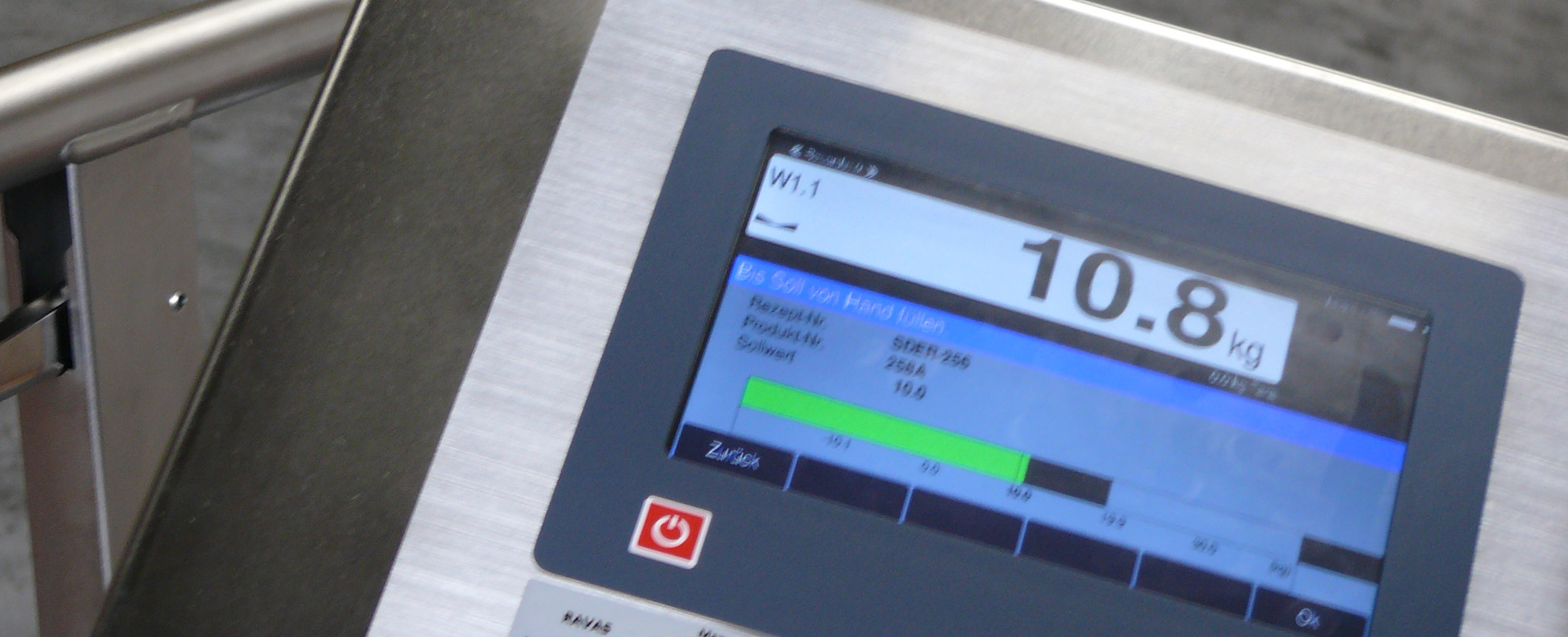

To avoid errors, and thus save time, it is important to use high-precision weighing systems whenever possible. RAVAS meets this need and is one of the international pioneers when it comes to integrating weighing and measuring technology into hand pallet trucks, forklifts and other material handling systems.

Maximum precision, maximum quality

Correct weighing and the food industry go hand in hand. Carefully choosing ingredient dosages ensures that products always produce the same consistency and quality, regardless of the production batch. This is especially important for pre-packaged products, where the consumer experience for customers must be consistent. At the same time, materials must be weighed accurately to meet food safety standards. For example, if an ingredient is presented in larger quantities, a potentially dangerous final product could be the result. We also talk about cost management, as correct weighing prevents waste and keeps spending within predefined limits: this is especially true in an industry where price competition is very high and margins are tight. Doing all these tasks correctly can reduce production times and increase revenues. But only the best technology can achieve these goals.

How to choose the best tools?

To reduce errors and save time in the food industry, it is necessary to use mobile weighing technology. Mobile weighing will reduce waiting times, minimize errors due to manual manipulation and simplify the process around dosing. Also, thanks to our data management solutions, most mobile weighing solutions can integrate with your production management software, such as a WMS or ERP system.

How RAVAS can support you

Depending on what you are looking for as a food manufacturer, we at RAVAS have different solutions to address your challenges. Based on the work to be carried out, we can recommend the best solution. Think of the choice between manual or electric pallet truck solutions or the choice of production equipment, according to GMP standards (Good Manufacturing Practices) or in stainless steel. In fact, most of the RAVAS range is available as stainless steel versions.

Materials

Essentially, the construction materials can be divided into three categories: steel, stainless steel (RVS) and construction according to GMP standards. Stainless steel has a smooth surface on which bacteria and dirt find it difficult to adhere, which makes the cleaning easier. Therefore, stainless steel is the ideal material for hygiene and is widely used in the food industry.

GMP

GMP-compliant pallet trucks are made of stainless steel, but not all stainless steel pallet trucks meet GMP standards. In that case, the frame of the truck undergoes an additional treatment that seals all cracks and holes, preventing dirt from accumulating. GMP standards are regularly applied in the food sector, but are only really necessary in the chemical and pharmaceutical industries. Many food producers can do very well with a stainless steel solution.

Weighing solution for every demand

When we talk about lower weights and high dosing accuracy, we often advise our customers to use a hand pallet truck. In the case of batching, where batches of sometimes more than a tonne are processed and transported over longer distances, the RAVAS RPW EL is a frequently suggested solution. Do you work at height above the mixing vessel for mixing or dosing your products? In that case, choose the RPW ST solution.

Learn more about our Mobile Weighing technology through our blogs

Through blogs, videos and other items, discover how a mobile weighing system can make your processes more efficient and cost-effective, generate management information, monitor the quality of your products and services and promote customer satisfaction.

Why you want to invoice customers based on weighed weight

Data Management: the de factual basis for smarter business processes

Save time, space and money with a Mobile Weighing System