What is ATEX?

Mobile weighing in ATEX zones.

Does your company work with flammable substances, explosive gases or dust particles? Then it is essential to understand what ATEX means and which guidelines apply. ATEX certification is required by law in work environments where there is a risk of explosion. This means that all equipment – including weighing systems – must meet strict safety standards to prevent sparking and static discharge.

Mobile weighing in ATEX zones, such as ATEX Zone 21 and ATEX Zone 22, is subject to requirements to ensure a safe working environment. But what exactly does ATEX stand for? How are these zones determined? And which explosion-proof weighing systems can you use to continue working safely? In this article, we explain everything about ATEX, the different zones and the role of explosion-proof mobile weighing systems.

ATEX explained

What is ATEX?

The term ATEX is derived from the French abbreviation for “ATmosphères EXplosibles” and refers to the European directives that determine how companies can work safely in potentially explosive environments. In an explosive environment, a small spark or static discharge can be enough to cause an explosion. This risk increases when using standard equipment that is not designed to function in ATEX zones.

Risks

Without ATEX-certified weighing systems, companies can face increased risk of explosion and danger to employees, legal sanctions or fines for non-compliance with ATEX directives, or production loss and damage due to explosions or fire.

The ATEX directives ensure that equipment and work environments meet strict safety standards to prevent explosions.

Companies that work with flammable gases, vapors or dust particles must divide their work environment into ATEX zones based on the risk of explosion. This is not only a legal obligation, but also crucial to protect employees and equipment from dangerous situations.

Henk Matser, Sales Manager OEM at RAVAS

“Some companies underestimate the impact of ATEX regulations until they have to deal with them. Our EXi weighing systems not only help customers comply with the legislation, but also make their processes safer, more efficient and more cost-effective.”

Where do the rules apply?

The different ATEX zones

To minimize the risk of explosions, companies that work with flammable substances must divide their work environment into ATEX zones. These zones indicate the likelihood of an explosive atmosphere developing and determine which safety measures and equipment are needed.

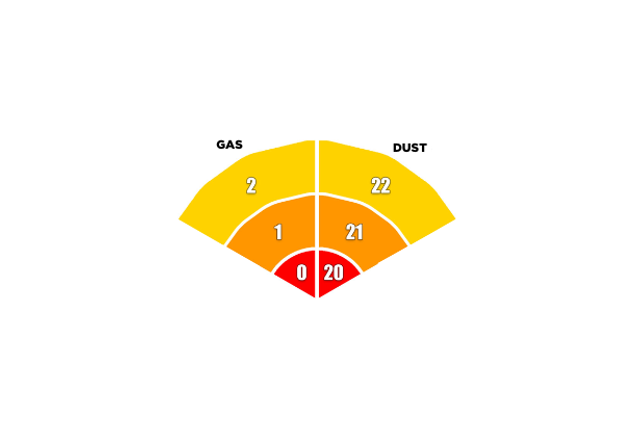

ATEX zones are subdivided into two categories: one for gas and vapor environments and one for dust environments.

ATEX zones for gas and vapor

- Zone 0: Explosive gases or vapors are present permanently or for long periods of time.

- Zone 1: Explosive gases or vapors occur occasionally, for example in the case of leaks.

- Zone 2: Explosive gases or vapors rarely occur, but there is a small risk.

ATEX zones for dust

- Zone 20: Explosive dust is present permanently or for long periods, such as in packaging or grinding processes.

- Zone 21: Explosive dust occurs occasionally, for example in the form of dust accumulation around machinery.

- Zone 22: Explosive dust occurs rarely, but there is a small risk.

Safety and efficiency

Mobile weighing in ATEX zones

Working in an ATEX zone involves strict safety requirements, but that does not mean that efficiency in the process has to be lost. Mobile weighing within ATEX zones offers companies in the chemical, pharmaceutical and logistics sectors a safe and practical solution.

Instead of moving materials to a fixed weighing location, the weighing process is integrated into the workflow, which has several advantages.

- Safe weighing without risk of explosion: thanks to intrinsically safe electronics, antistatic wheels and non-sparking materials, mobile weighing systems comply with ATEX directives and minimize the risk of explosions.

- Time savings and higher efficiency: Materials can be weighed directly in the workplace, eliminating unnecessary transportation within the factory and increasing productivity.

- Less chemical waste and lower costs: Because ingredients are weighed directly into a mixing tub or barrel, pipes and pumps stay cleaner, which reduces waste and waste processing costs.

- Optimized ergonomics and less physical strain: Operators need to move heavy barrels or pallets less often, which reduces physical strain and creates a safer work environment.

- Direct data exchange for better business operations: Weighing data can be sent directly to WMS, ERP or TMS via wireless connectivity, providing real-time insight and more efficient decision-making.

Customer story

Herberts / Global Paint Products

Explosion-proof mobile weighing can make a big difference in speed and efficiency. Herberts, a specialist in industrial coatings, optimized their production process with the RAVAS ProLine 2100 EXi. By weighing directly on the pallet truck, they saved time, reduced product loss and improved safety in their ATEX-certified work environment.

Discover how Herberts lifted their process to a higher level with explosion-proof weighing.

ATEX-certified

Discover our pallet trucks

RAVAS 2100 EXi

An explosion-proof hand pallet truck specially designed for hazardous environments. ATEX certified and fitted with stainless steel fork shoes.

- Weighing capacity: 2,000 kg

- Scale part: 0.2 - 1 kg

- Optional: calibrated version class OIML III, completely stainless steel

RAVAS 2560 EXi

The RAVAS 2560 EXi is an explosion-proof pallet truck with integrated scale, specially designed for use in hazardous environments.

- Weighing capacity: 2,000 kg

- Scale part: 0.2 - 1 kg

- Optional: calibrated version class OIML III or wifi

RAVAS ProLine 2560 EXi

Discover the RAVAS 2560 EXi, a high-precision, explosion-proof pallet truck with integrated scale and stainless steel fork shoes. Ideal when accuracy and safety are both priorities.

- Weighing capacity: 2,000 kg

- Scale part: 0,1 - 0,5 kg

- Optional: calibrated version class OIML III or wifi